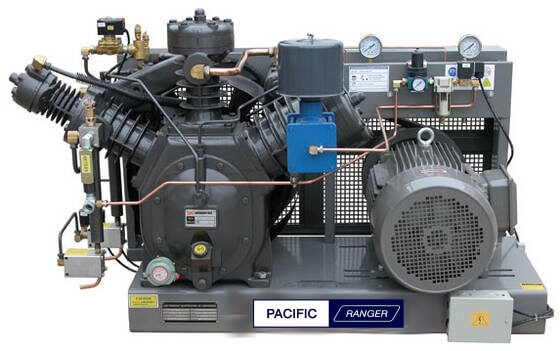

Pacific Ranger Oil-Free Piston Compressors

Quiet. Clean. Reliable. Engineered for Precision.

Looking for a dependable source of clean, oil-free compressed air? Pacific Ranger’s oil-free straight piston compressors are designed for industries where air purity, low noise, and long-term reliability are essential. Available in power ranges from 0.75 HP to 20 HP, our compressors are built to perform in demanding environments while minimizing maintenance and operating costs.

🌿What is an Oil-Free Piston Compressor?

An oil-free piston compressor, also known as a reciprocating oil-less air compressor, delivers compressed air without using oil for lubrication. These systems run at reduced RPMs, making them quieter, more efficient, and ideal for sensitive applications where oil contamination is unacceptable.

🔍Oil-Free vs. Oil-Lubricated Compressors: Key Differences

| Feature | Oil-Free Compressor | Oil-Lubricated Compressor |

|---|---|---|

| Lubrication | No oil needed | Requires oil |

| Maintenance | Low | Higher (regular oil changes) |

| Weight | Lighter | Heavier |

| Air Purity | 100% Oil-Free | Potential for oil carryover |

| Ideal For | Cleanroom, medical, lab use | High-pressure, heavy-duty use |

Oil-free compressors are perfect for facilities requiring clean air, low noise, and easy maintenance.

✅Benefits of Pacific Ranger Oil-Free Compressor Technology

• 🔧 Maintenance-Free Operation

No oil changes or filter replacements related to lubrication.

• 💨 Contamination-Free Air

Ideal for medical, dental, food-grade, and electronic applications.

• 🔇 Ultra-Quiet Design

Built for noise-sensitive environments.

• ⚡ Energy Efficient

Operates at lower RPMs, reducing energy consumption and wear.

• 📜 Compliant with ISO and Regulatory Standards

Designed for use in regulated environments.

• 🛠️ Corrosion-Resistant Tanks

CRN-certified air tanks built to last.

🔗Applications Across Industries

Pacific Ranger’s oil-free piston compressors are trusted across a variety of sectors:

• 🏥 Medical and Dental Clinics

• 🧪 Laboratories and Pharmaceuticals

• 🍽️ Food & Beverage Processing

• 💻 Electronics and Cleanroom Manufacturing

• 🚗 Automotive Paint and Finishing Shops

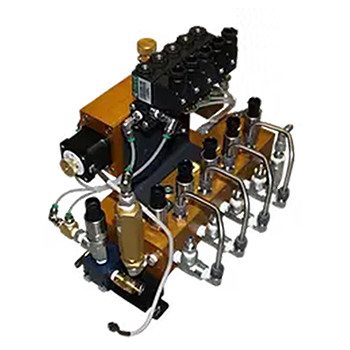

🔧Custom Compressor Packages Available

To meet diverse application needs, we offer modular compressor packages with:

• ❄️ Aftercoolers for moisture removal

• 🧼 Multi-stage air filtration systems

• 💧 Desiccant air dryers

• 🔕 Sound-reducing cabinets for quiet operation

• 🛠️ Easy plug-and-play installation kits

⭐Why Choose Pacific Ranger?

Pacific Ranger is a trusted name in industrial air solutions. Our compressors are:

✔ Built for reliability and longevity

✔ Compliant with strict air quality and safety standards

✔ Supported by expert service and technical guidance

✔ Designed and tested to perform in mission-critical environments

📞Ready to Upgrade to Oil-Free?

Discover the power of Pacific Ranger’s clean air compressor solutions. Contact our team today for a customized quote, technical specs, or distributor information.